Non-Destructive Testing: the key to safe and effective munitions inspection

Non-destructive testing (NDT) is used to evaluate the properties of a component without causing damage to it. In the context of munitions, NDT can be used to assess the integrity and reliability of various artillery parts, such as shells, bullets, and other types of armaments.

The Military uses NDT techniques to ensure that munitions are safe to use and will function as intended. For example, NDT can be used to detect defects in the metal casings of shells or bullets, such as cracks, voids, or other flaws that could compromise their performance. By identifying these issues early on, the Army can take steps to repair or replace the defective components, thereby reducing the risk of accidents or malfunctions in the field.

In addition to detecting defects, NDT can also be used to monitor the aging and wear of munitions over time and their safe disposal. This can be important for ensuring that older munitions are still safe and effective to use, and for identifying potential issues before they become serious problems.

Overall, NDT plays an important role in ensuring the safety and reliability of munitions used by the Army and helps to ensure that soldiers can carry out their missions effectively and safely.

What are the advantages using of digital radiography (DR) panels?

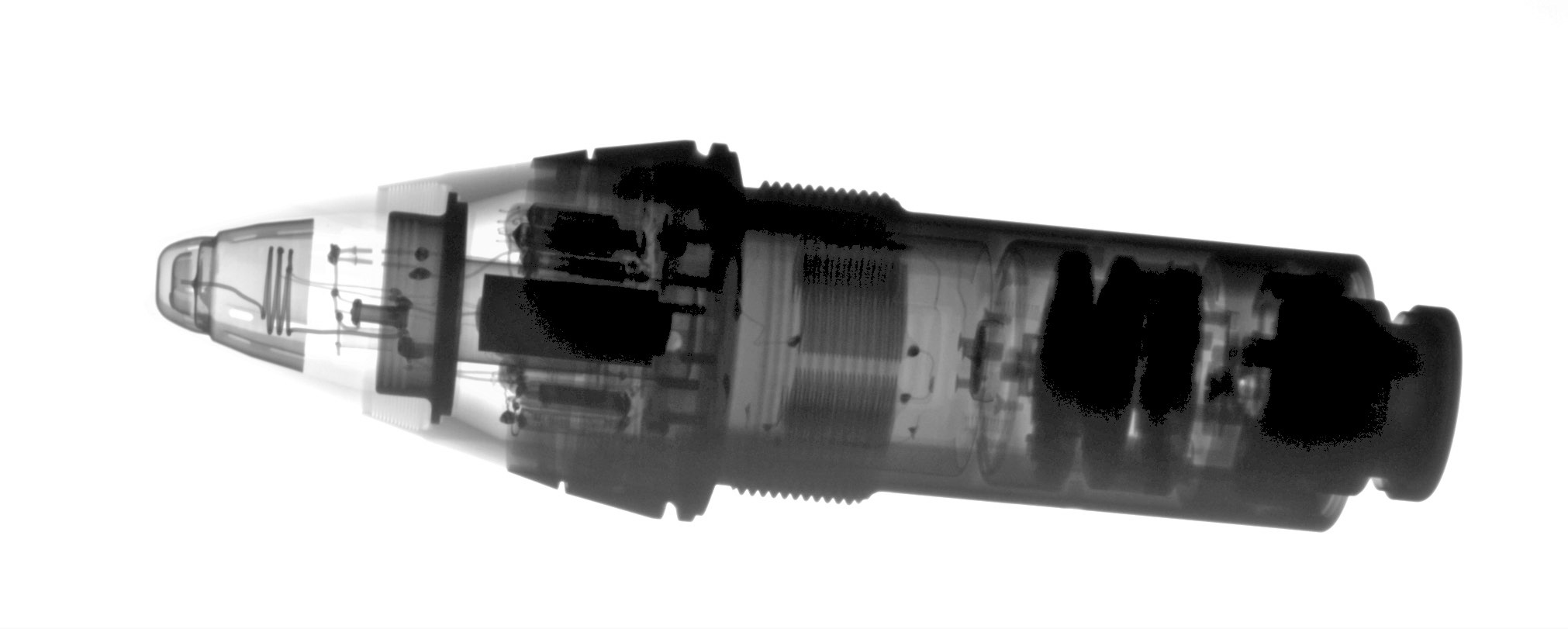

Digital radiography is one of the NDT techniques on offer for the military it uses x-rays or gamma rays to create a digital image of the internal structure of an object. In the context of munitions NDT, DR can be used to inspect the internal components of shells, bullets, and other types of artillery, to discover any defects or voids hidden from view which could compromise performance without damaging or disassembling the item.

How does it compare to traditional film-based radiography?

Compared to traditional radiography techniques, which use film to capture images, DR offers several clear advantages.

digital images can be processed and analysed more quickly, stored easily and shared electronically. This makes it easier for NDT technicians to identify and track potential issues.

digital radiography produces higher quality images with greater clarity and detail, which can improve the accuracy of NDT inspections. This can be especially important in the context of munitions, where even small defects or irregularities can have serious consequences in combat.

Lightweight DR panels are portable and easy to use in the field. The image quality of DR means better images can be achieved at lower x-ray dose levels so it is safer for the technician to work with.

Overall, digital radiography is an important tool in the arsenal of NDT techniques used to inspect munitions and ensure their safety and reliability. By providing detailed images of internal components, digital radiography helps to identify potential issues and prevent accidents or malfunctions in the field.

Why choose Scanna as your partner for Military NDT?

For over 30 years, Scanna has been supplying portable x-ray systems and other detection equipment for the security and military sectors globally. Scanna x-ray equipment is trusted in more than 100 countries and is used with Government, Military, Police and Specialist Agencies. With operations in the UK and USA, Scanna offers on-site training and support wherever our clients have a presence around the globe.

Case Study: Inspecting the interior of artillery shells. Artillery shells are designed to withstand high levels of stress and pressure during firing, which can cause defects such as cracks or voids in the shell casing or internal components. If these defects go undetected, they can compromise the integrity of the shell and lead to accidents or malfunctions in the field.

To prevent these issues, the army can use digital radiography to inspect the internal components of artillery shells without damaging them. DR can be used to create high-resolution images of the interior of the shell, which can reveal any defects or irregularities in the casing or other components. By identifying these issues early on, the army can take steps to repair or replace the defective components and ensure that the shell is safe and reliable to use in the field. Scanna offers DR panels in a range of sizes to suit your application: 10 x 24 cm, 18 x 24 cm, 24 x 30 cm, 36 x 43 cm and 86 x 86 cm. Click here for more information.

Case Study: Rocket Non-Destructive Examination (NDE)

The non-destructive evaluation of rockets has a primary focus of keeping the operators safe by utilizing x-ray to enable the safe destruction of the rockets. DR x-ray is used to inspect the internal structure of rocket firing tubes, in order, to identify any leaking agent prior to cutting the rocket open and removing the warhead. This ensures that no leaking agent would be exposed in the main rocket processing line and eliminates potentially dangerous conditions and costly shutdowns. DR can be utilized to identify which rockets can be safely destroyed and disposed of.

Other examples of military components that the army may want to inspect using digital radiography NDT include the propellant charge in rocket motors, the fuses and detonators in bombs. In all these cases, digital radiography can help to identify potential issues and prevent accidents or malfunctions in the field. For more information contact the team at Scanna.