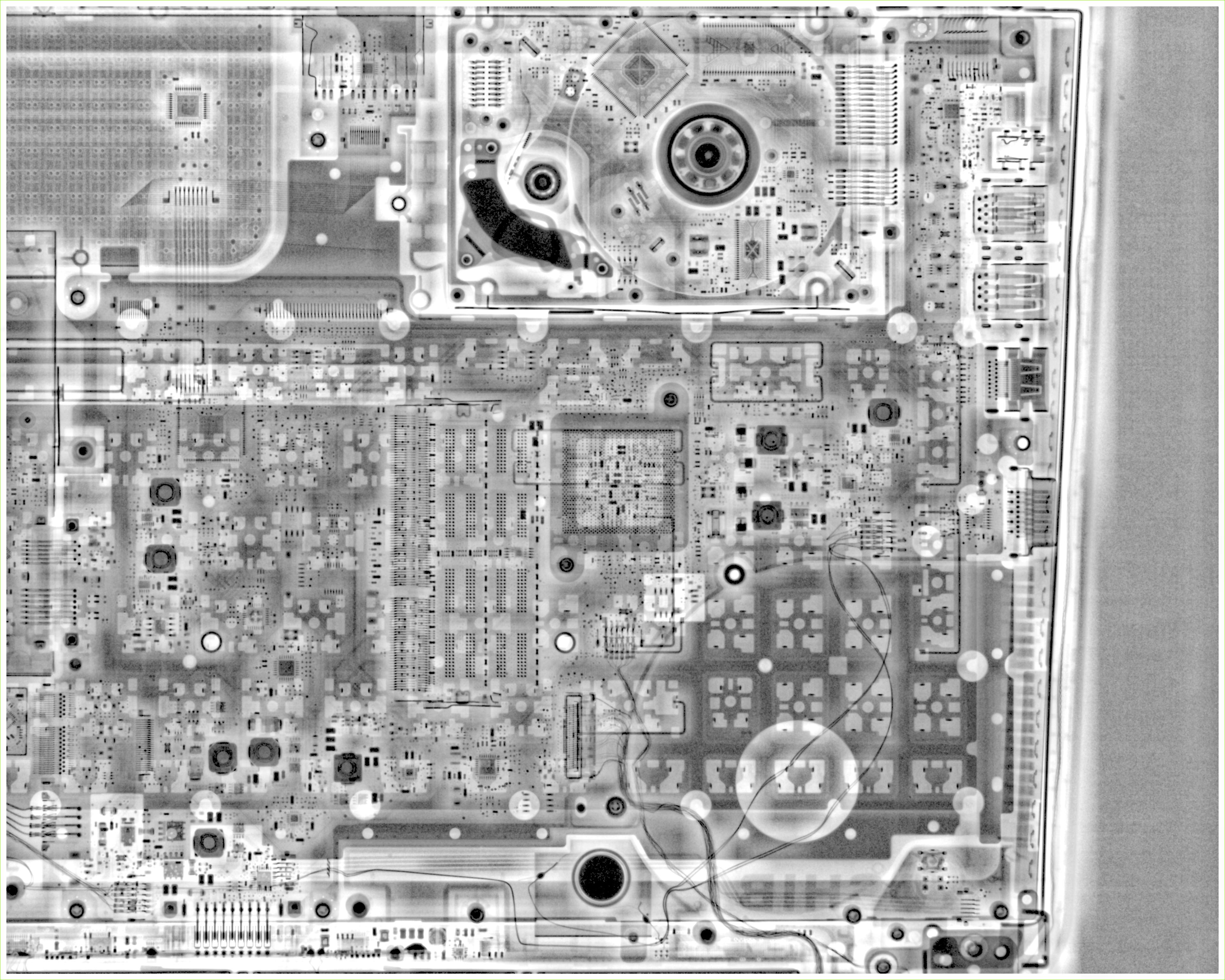

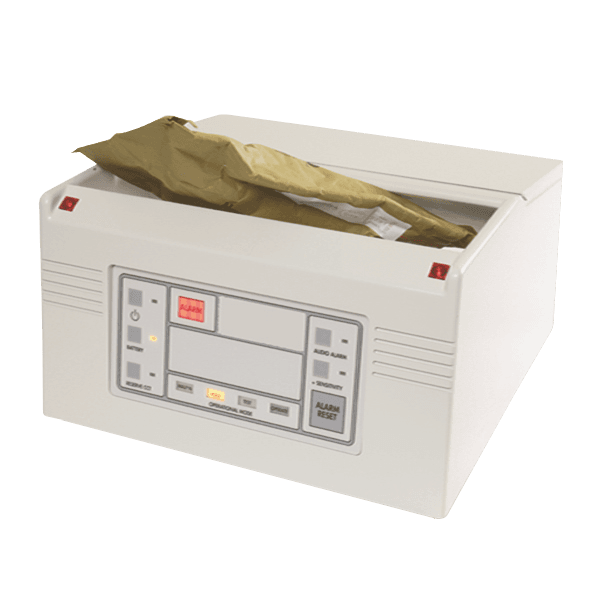

Portable X-Ray Systems

Searching for the perfect portable x-ray system to assist with a specific security task?

Whatever your mission, Scanna offers you the widest range of high resolution DR (Direct Radiography - rugged intelligent x-ray imagers, no processor) and CR (Computed radiography - flexible electronic free x-ray plates with processor) portable x-ray systems for security and defense applications.

At Scanna we believe in the operator's choice to have the appropriate x-ray screening tool available for their task. We understand you sometimes need custom solutions that combine dual DR X-ray detector panels in different sizes, CR and DR x-ray plates that run from the same operating platform, X-ray panels for use with your own x-ray sources and specialised imaging software, backpack solutions, covert solutions, x-ray detectors for special projects, NDT variants...

So whether you need to check suspicious packages and bags, screen vehicles or carry out forensic exploitation work, contact Scanna today. We have the perfect x-ray system for you.

View